[Infographic] A Handy Guide to Modular Vehicle Platforms

Manufacturers are producing wider and wider varieties of vehicles, requiring multi-use underbodies that provide the main building block for diverse products. Manufacturers can use a common architecture for the chassis and basic components of multiple designs and models. This lowers costs by condensing production and delaying differentiation until further in the process.

Mechanics in training might be surprised to discover how many vehicles share platforms, but look completely different and appeal to entirely different drivers. By using uniform platforms on different vehicles, auto manufacturers can make parts in greater volumes to be added on, not only lowering manufacturing costs but also reducing design, engineering, and testing costs and labour.

Modular platforms are flexible and can be adjusted for size to match larger or smaller vehicles. These platforms can also be adapted and modified for future designs, further dispersing costs into years ahead. After automotive school you may start to notice similarities due to these modular platforms—it might even help you service different cars, by understanding their common building blocks. Read on for some quick facts about modular vehicle platforms!

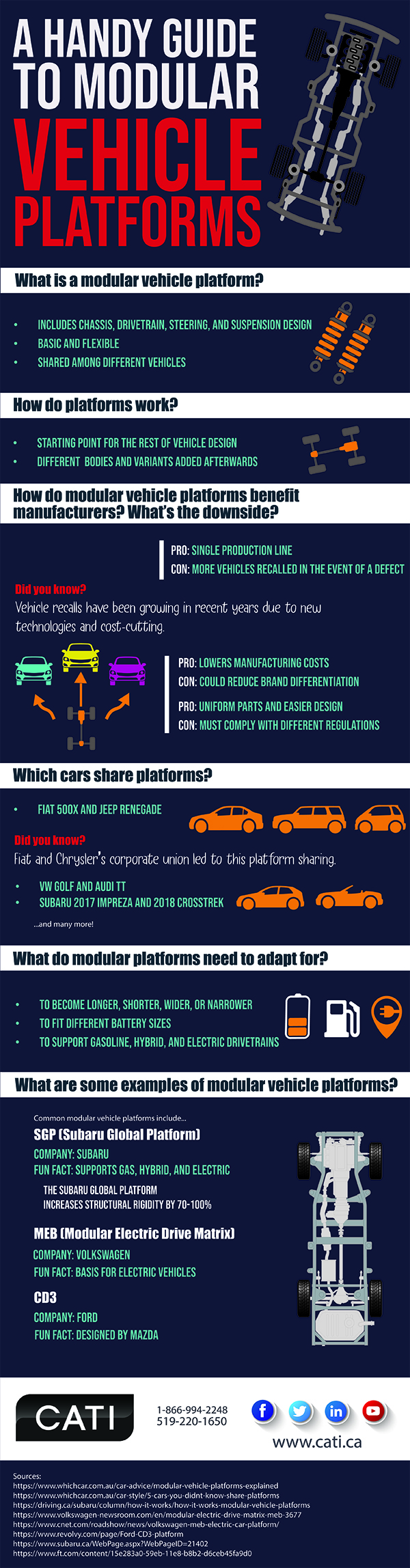

A Handy Guide to Modular Vehicle Platforms

What is a modular vehicle platform?

• Includes chassis, drivetrain, steering, and suspension design

• Basic and flexible

• Shared among different vehicles

How do platforms work?

• Starting point for the rest of vehicle design

• Different bodies and variants added afterwards

How do modular vehicle platforms benefit manufacturers? What’s the downside?

PRO: Single production line

CON: More vehicles recalled in the event of a defect

Did you know?

Vehicle recalls have been growing in recent years due to new technologies and cost-cutting.

PRO: Lowers manufacturing costs

CON: Could reduce brand differentiation

PRO: Uniform parts and easier design

CON: Must comply with different regulations

Which cars share platforms?

• Fiat 500X and Jeep Renegade

Did you know? Fiat and Chrysler’s corporate union led to this platform sharing.

• VW Golf and Audi TT

• Subaru 2017 Impreza and 2018 Crosstrek

…and many more!

What do modular platforms need to adapt for?

• To become longer, shorter, wider, or narrower

• To fit different battery sizes

• To support gasoline, hybrid, and electric drivetrains

What are some examples of modular vehicle platforms?

Common modular vehicle platforms include…

SGP (Subaru Global Platform)

Company: Subaru

Fun Fact: Supports gas, hybrid, and electric

The Subaru Global Platform increases structural rigidity by 70-100%

MEB (Modular Electric Drive Matrix)

Company: Volkswagen

Fun Fact: Basis for electric vehicles

CD3

Company: Ford

Fun Fact: Designed by Mazda

Sources:

https://www.whichcar.com.au/car-advice/modular-vehicle-platforms-explained

https://www.whichcar.com.au/car-style/5-cars-you-didnt-know-share-platforms

https://driving.ca/subaru/column/how-it-works/how-it-works-modular-vehicle-platforms

https://www.volkswagen-newsroom.com/en/modular-electric-drive-matrix-meb-3677

https://www.cnet.com/roadshow/news/volkswagen-meb-electric-car-platform/

https://www.revolvy.com/page/Ford-CD3-platform

https://www.subaru.ca/WebPage.aspx?WebPageID=21402

https://www.ft.com/content/15e283a0-59eb-11e8-b8b2-d6ceb45fa9d0