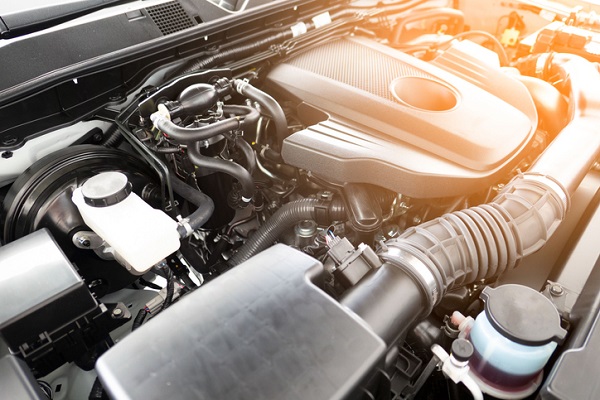

A Guide to Fixing Vacuum Leaks for Students in Automotive College

They’re not always easy to spot, but they need to be fixed regardless! A vacuum leak in a car’s engine can happen when the engine’s air-to-fuel ratio exceeds 14.7:1 (also known as a lean mixture), and excessive, unwanted air in the engine occurs as a result. This leads to a subpar performance from the engine—if it even runs at all—and can also pose numerous problems for drivability.

Identifying and fixing the leak, and diagnosing what might be causing the problem, are important to learn about, and there are many ways auto mechanics can go about correcting them. Here’s how automotive college students can fix vacuum leaks in an engine.

There are Various Symptoms Worth Watching Out For When it Comes to Vacuum Leaks

While there are many problems that can lead to vacuum leaks, some of the most notable include if there is damage to the engine, the engine not running properly, the release of oxide emissions (and generally poor fuel economy), and the check engine light being on and not compensating for unmetered air. Vacuum leaks often make hissing noises, though leaks can also be present if no noises are audible, or if the running engine makes it impossible to hear the hissing noise. Certain situations such as rough or high idles, the engine stalling or misfiring, or generally lacklustre brake performance can be problems pointing towards a possible leak. One of the most crucial parts to know about fixing vacuum leaks when becoming a mechanic isn’t just how to fix it, but what the underlying problems are.

What Students in Auto Mechanic Training Should Look For In Identifying Vacuum Leaks

Figuring out where the vacuum leaks are happening is fairly easy. You can start by looking through the vacuum hose diagram either on a sticker under the car’s hood or in the car’s manual. Then, you can start troubleshooting to identify the leak using one of several methods, including the water method (using a spray bottle of water around areas where leaks are suspected to be), visual checks, a mechanic’s stethoscope, or a carb cleaner (though this material is flammable, so use caution!). You can also use a smoke machine, as this is widely considered the safest and often the most successful tool for identifying vacuum leaks.

There are Several Ways it Can Be Fixed—and Reasons Why it’s Important, Too

Since a car’s engine sensors and power brakes use intake vacuum to power them with, even a small leak can mislead the sensors and the vehicle’s computer as a whole into thinking a certain component of the vehicle needs to be fixed. Students in automotive college should know that if a vacuum hose is damaged, simply repairing it is often sufficient instead of replacing it entirely. In some cases, if one is split at the end, you can simply cut it off and then reconnect it. However, be sure to fix one vacuum hose at a time, for the sake of not getting any of them confused. If the hose has hardened or is rotten, you’ll need to replace it.

If the issue is the intake manifold gasket, re-torque the intake manifold bolts. Should this be unsuccessful, you’ll need to replace the intake gaskets and remove the manifold. With EGR valve leaks, you can try to clean it if the valve won’t completely close. With carburetors or throttle bodies, try repairing the base by tightening either of those parts, and replace the gasket underneath them if the leak continues. If the issue is with the shaft of either the throttle body or carburetor, you’ll have to resleeve it—in other words, replacing them with a new unit.

Want to start your auto mechanic training?

Contact CATI for more information!