Starting Auto Mechanic School? Here’s a Detailed Look at Leaf Springs and What They Do

If you’re considering or are about to begin automotive school, you’ll soon become familiar with the ins and outs of vehicles, including their body, frame, engine and the many parts and components that keep them moving. During your training program, you might be surprised by the many components you weren’t previously aware of but serve an important function in certain vehicles. One such part is the leaf spring. These handy parts have been around since the Middle Ages and were eventually patented by British inventor Obadiah Elliot in 1804. Back then, they were used for the wheels of horse-drawn carriages, but today leaf springs are found within heavier vehicles like commercial trucks or vans.

Below, learn more about what leaf springs are, the different types of leaf springs, when you may encounter them throughout your career as a mechanic and more.

What Are Leaf Springs?

In simple terms, leaf springs are a suspension mechanism for a vehicle and are commonly found in heavy trucks and vans. They provide support, create a smoother ride, and absorb potholes and uneven surfaces so that drivers and passengers remain safe and comfortable on the road. For SUVs, vans and other larger vehicles, leaf springs serve an important function; however, as you’ll learn in auto mechanic school, many people know nothing about them until it’s time to repair them.

Leaf springs are made up of several layers of “leaves,” or thin pieces of steel that are attached to one another. The leaves gradually become smaller in size from top to bottom, forming a slight curve. Leaf springs are attached to the chassis and rear axle of a vehicle, and they help to absorb additional weight from passengers or cargo, preventing the axle from experiencing strain or breakage due to pressure.

What Kind of Leaf Springs Can You Expect to See in Automotive School?

There are two different types of leaf springs, including longitudinal and transverse springs. What’s the difference? Longitudinal leaf springs are used on rigid axles. As an auto mechanic, you’ll encounter these on commercial vehicles and trailers. Transverse leaf springs can provide springing on both sides of a vehicle’s axle and are mounted to the chassis and attached to a wheel carrier. In your car mechanics training and on the job, you might see transverse leaf springs utilized more commonly in high-performance vehicles, like sports cars. Both kinds of leaf springs are necessary for heavy-duty trucks, in farming, and industrial vehicles, making it possible to carry heavy loads.

The Pros and Cons of Leaf Springs

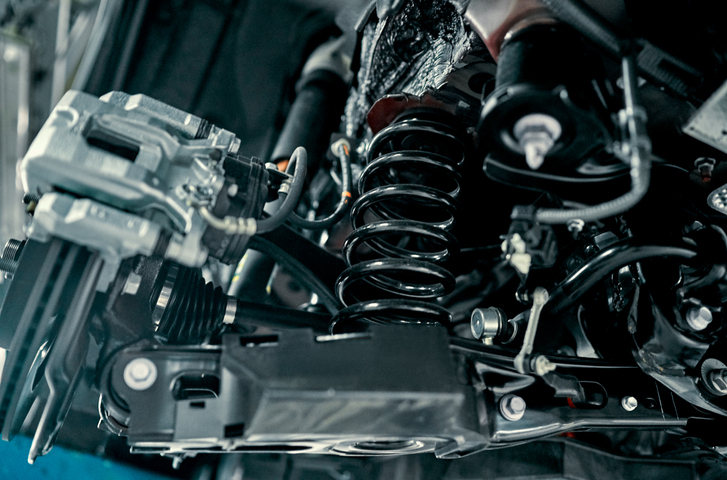

Relatively cheap to produce, leaf springs have a long list of advantages. As mentioned, they help vehicles carry heavy loads and act as shock absorbers. However, there are a couple of notable pitfalls when it comes to leaf springs. One major disadvantage is the lack of suspension adjustability. When it comes to certain driving styles like racing and performance driving, this problem is easily solved with the addition of adjustable coil overs, which makes them a popular choice for certain vehicles. In most cases, leaf springs can only move vertically, limiting their range of motion. In addition, though leaf springs make for extremely effective shock absorbers, compared to modern suspension solutions, they cause erratic bouncing when driving over bumps and potholes. While leaf springs are certainly advantageous for heavier vehicles, today, we’re seeing more vehicles transition to modern suspension systems as technology advances.

Are you ready to start your auto repair training?

Contact CATI for more information!