As long as there have been internal combustion engines, there has been the need to power the engine in a synchronized manner to keep the vehicle running smoothly and safely. Timing belts and timing chains both serve this function. They work by synchronizing the rotation of the crankshaft (which moves pistons up and down within the engine’s cylinders) with the camshaft (which allows the inlet and outlet valves to open and close at the right time), permitting the right amounts of gasoline and air to enter the engine. Both are maintained by tensioners, which preserve the proper movement of the part. While the engine relies on a timing belt or a timing chain for the same purpose, there are major differences between these two parts, which drivers and mechanics alike should be aware of when maintaining a vehicle.

Timing Chains and Timing Belts Explained for Those in Auto Mechanic School

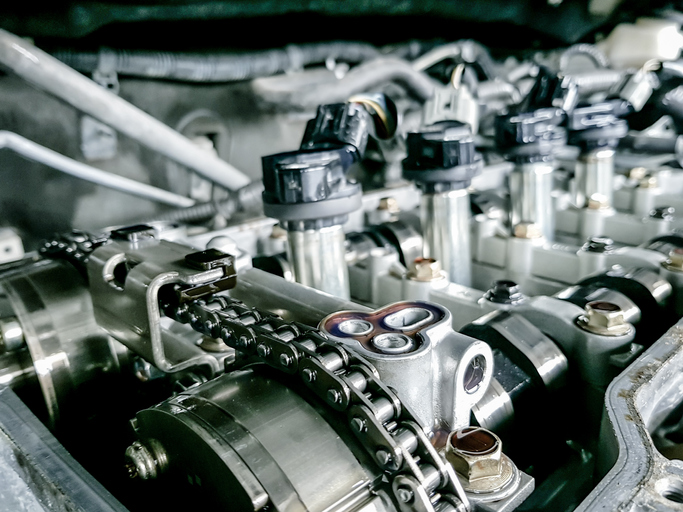

Timing chains, similar in appearance to the chain of a bicycle and made from metal, were invented along with the internal combustion engine in 1890. When timing belts came along in the 1940s, their popularity decreased, which is why those in auto mechanic college may encounter them less frequently in vehicles. However, since 1990, timing chains have experienced a resurgence among manufacturers such as Mercedes Benz, Volkswagen, and BMW. Timing chains use a metal sprocket and chains to transfer motion from the crankshaft to the camshaft, and their tensioners depend on hydraulic pressure.

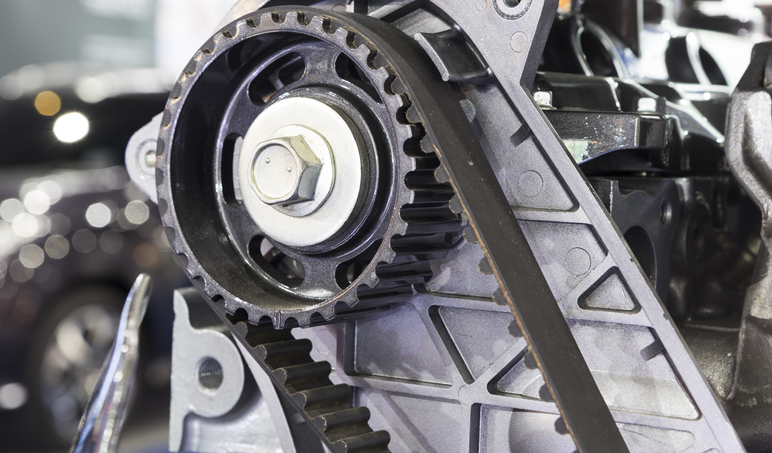

Timing belts came along in 1940, when Pontiac released a 6-cylinder engine which utilized a rubber strap rather than a chain. From then on, these belts gained greater popularity than the chain. Timing belts are made from rubber fortified with fiberglass, equipped with little teeth acting as gears to transfer movement from shaft to shaft.

Advantages of Timing Chains

Timing chains have a few features that stand out against timing belts. For one, because they are made of metal, they last longer than belts, in some cases lasting the lifetime of the car. Timing belts last between 60,000 – 100,000 km, whereas timing chains, if they need replacing, can be replaced at around 250,000 – 300,000 km. A timing chain may not need to be changed at all if a driver properly maintains their car by monitoring oil levels. A timing chain needs to be lubricated, and having oil of a sufficient amount and quality in the engine at all times is important in keeping it working well. Another advantage to a timing chain is that it will remind a forgetful driver when it needs to be changed, unlike a timing belt, which a driver must remember to change before it’s too late. Lastly, while a timing belt may change length depending on the temperature and is generally more susceptible to wear due its rubber manufacturing, a metal timing chain has a much lower risk of breaking. Those in car mechanics training are probably less likely to encounter a timing chain that needs fixing.

Advantages of Timing Belts

Timing belts are naturally much quieter (no metal on metal contact) and lower cost than timing chains—a big reason for their rise in popularity. Timing belts are much lighter, they are resistant to rust, and they allow the engine to perform at a higher range of speed. Because timing belts do not require lubrication from oil, their performance is not related to oil pressure in the way that timing chains are. If the oil pressure is too low in a car with a timing chain, the chain could fail, as its tensioner depends on hydraulic pressure.

Are you interested in auto mechanic school?

Check out CATI’s programs today.